Share to

ERW Tube Mill Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Details

-

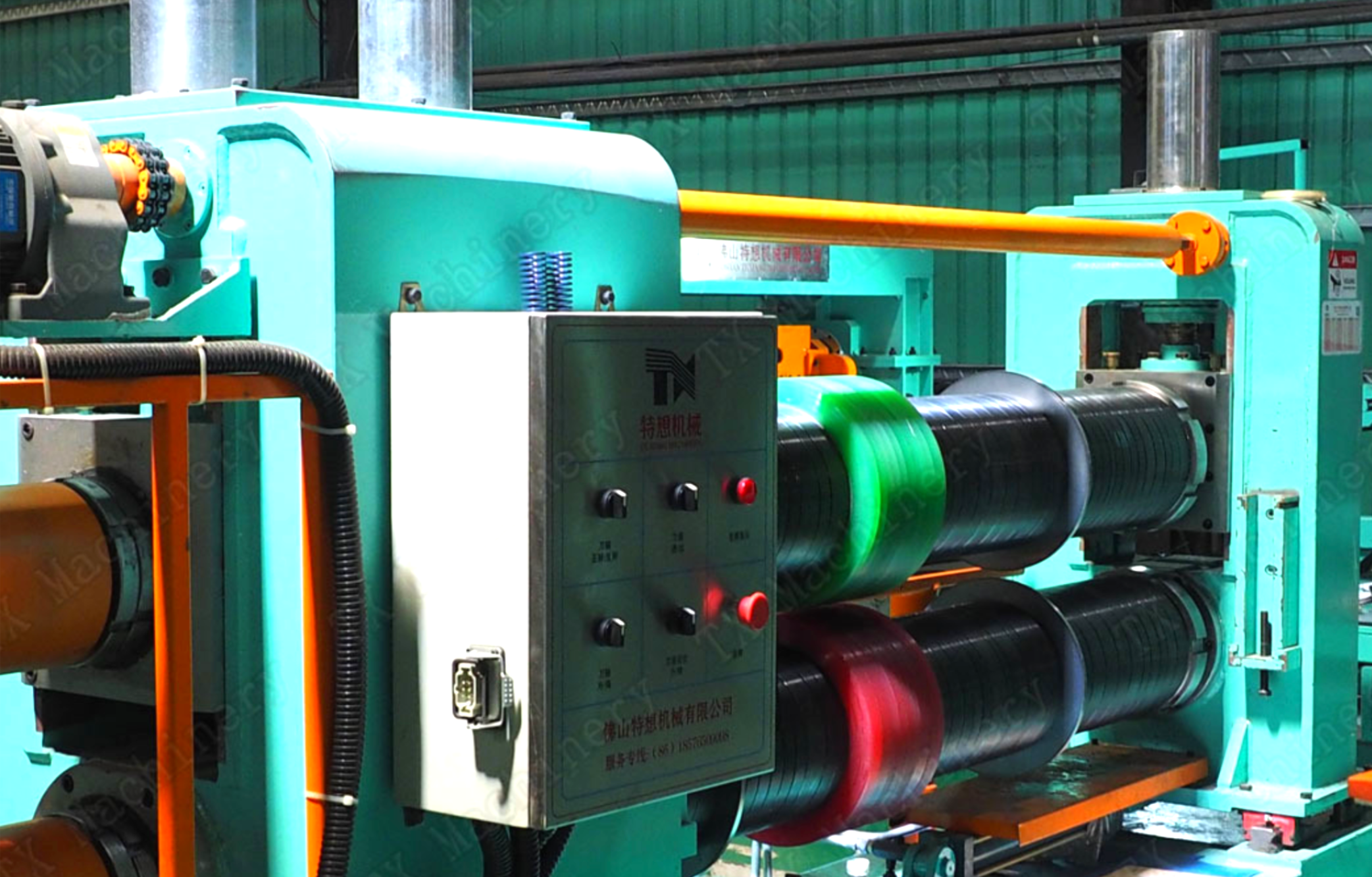

ERW Tube Mill Line

PRODUCT INTRODUCTION

Composition: Hydraulic decoiler, pinch roll+straightener,shear and welder, horizontal spiral accumulator, forming & sizing machine, flying saw/cold saw, runout table & discharge unit

Main technical parameters:

Model

Pipe Diameter

Pipe Thickness

Main Motor

High frequency

motor

Welding

speed

HG16

φ7-φ16mm

0.5-1.0mm

30kw

100kw

10-90m/min

HG32

φ13-φ38mm

0.7-2.5mm

55kw

150kw

10-70m/min

HG50

φ16-φ50mm

0.8-3.0mm

90kw

200kw

10-70m/min

HG76

φ30-φ76mm

1.5-4.0mm

132kw

250kw

10-60m/min

HG114

φ60-φ114mm

2.0-5.0mm

160kw

300kw

10-50m/min

HG165

φ76-φ165mm

2.0-6.0mm

264kw

400kw

10-40m/min

HG219

φ114-φ219mm

3.0-6.0mm

464kw

500kw

10-30m/min

HG325

φ140-φ325mm

4.5-10mm

600kw

600kw

10-25m/min

Hydraulic uncoiler: Support strip and provide raw material for the production line.

Accumulator: Store a certain amount of steel strips for feeding the production before the strips ends welding, so as to guarantee the continuous production while the ends welding.

Forming and sizing machine: Continuously roll the specified steel strip into pipe shape and weld it into pipe. It could produce round pipe, square pipe,rectangular pipe and special pipe.

High frequency solid state welder: Induction welding. By means of skin effect and proximity effect of high frequency current, current highly concentrates on the edges of strips and heat it quickly. thru the cooling, sizing,straightening to form the pipes with required specification.

Flying saw: Automatic cut to length of the pipes with different shapes in high precision at high speed. By using high speed and precision STD control system and mechanical system, length measuring and synchronization is in high level.

Roller table and discharge table: Alignment for both ends of the tube so as to be convenient for packing.

ERW Tube Mill Line

Still deciding? Contact US !

Classification

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Content update in progress